CNC Testing - An Essential That Tool In The Bottom Of Manufacture Comunity

Developers are tasked with precision and speed in the fast-paced landscape of product development. This is where CNC (Computer Numerical Control) prototyping services play an important role, enabling developers and engineers to quickly convert their conceptual designs into physical products. These materialise cnc rapid prototyping technology use advanced CNC machinery to generate exact functional prototype parts swiftly, successfully andean easily with a high level of repetition.

Quickly Validating the Design

Fast Prototyping

CNC prototyping services are noteworthy for a variety of reasons, one of which is their speed of prototyping. It enables designs to be created into operational prototypes within days as opposed to several weeks of using traditional methods. This is essential for iterative design processes where numerous versions of a component are necessary to test and improve a concept. For instance, the Precision you get with the CNC machining (up to ±0.005 inch), has enabled engineers to test designs and functions more rapidly.

Precision and Consistency

Creating a perfect copy according to Design specifications

CNC prototyping provides a whole new level of precision to product development. Because of the CNC process being digital in nature, the parts created can be controlled by the CNC program down to nearly an exact design specification. Such high accuracy is critical for parts that have very specific dimensional fits and must perform at high stakes, like in aerospace or medical applications.

Good for HighVolume-LowMedium Volume

Saving in Product Development

The expenses involved in starting a CNC process can be heavy but the cost per unit in prototyping can be much lower compared to other manufacturing techniques for relatively low to medium volume productions. This cost efficiency comes from the fact that CNC prototyping does not involve the use of costly molds or appliances. A common setup and tools bundle is used to machine a variety of features, rather than using entirely new tools and setups to create different features, greatly mitigating the non-recurring engineering costs associated with a product development effort.

Material Versatility

Wide Assortment of Materials Applicable

The limitation of the material is not confined in case of prototyping, CNC prototyping can be done on any type material that is why is so versatile in various industries. What Is It Used ForIt is capable of machining materials from plastics (POM, PEEK, PP, ABS, PA, etc) to wood and metallic materials (Aluminium, tool-steel, titanium). This flexibility allows product developers to try out various materials to determine the best balance of strength, weight, and cost, helping to maximize the strength and appeal of the finished product.

Enhanced Innovation

Support for Advanced, Individual Designs

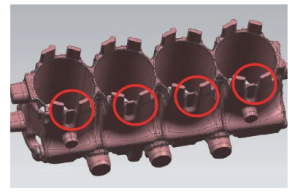

CNC prototyping services can give engineers all the freedom they need when it comes to design. For example, CNC machines can easily deal with complex geometries that are either very difficult or impossible to produce using traditional manufacturing methods. Beyond making parts look good, the ability to perform secondary operations benefits products with added functionality (correlating to performance and weight and consolidation of parts).

To me, this could be the product development of the future.

For today's new product development, the role of CNC prototyping services is very important. They speed up the design process, improving accuracy, are cost-effective and provide a better material and design range. The role of CNC prototyping is only set to grow as technology of evolves and the need for faster innovation cycles becomes more pertinent, with its place as an essential fixture within the engineering and manufacturing industries set to only further entrench.